Prismatic powders, with their captivating iridescence and unique optical properties, are increasingly utilized across diverse industries. These finely milled materials, characterized by their specific shapes and size distributions, exhibit fascinating light-scattering behaviors, leading to a wide array of applications. From enhancing the vibrancy of cosmetic products to creating stunning special effects in art and design, prismatic powders offer a unique blend of aesthetics and functionality.

This exploration delves into the manufacturing processes, chemical compositions, optical properties, and diverse applications of these remarkable materials.

The creation of prismatic powders involves sophisticated manufacturing techniques, resulting in particles with precisely controlled shapes and sizes. These techniques influence not only the visual appeal but also the performance characteristics of the final product. The material composition itself plays a critical role, determining factors such as stability, color, and interaction with light. Understanding these fundamental aspects is crucial for harnessing the full potential of prismatic powders in various fields.

Introduction to Prismatic Powders

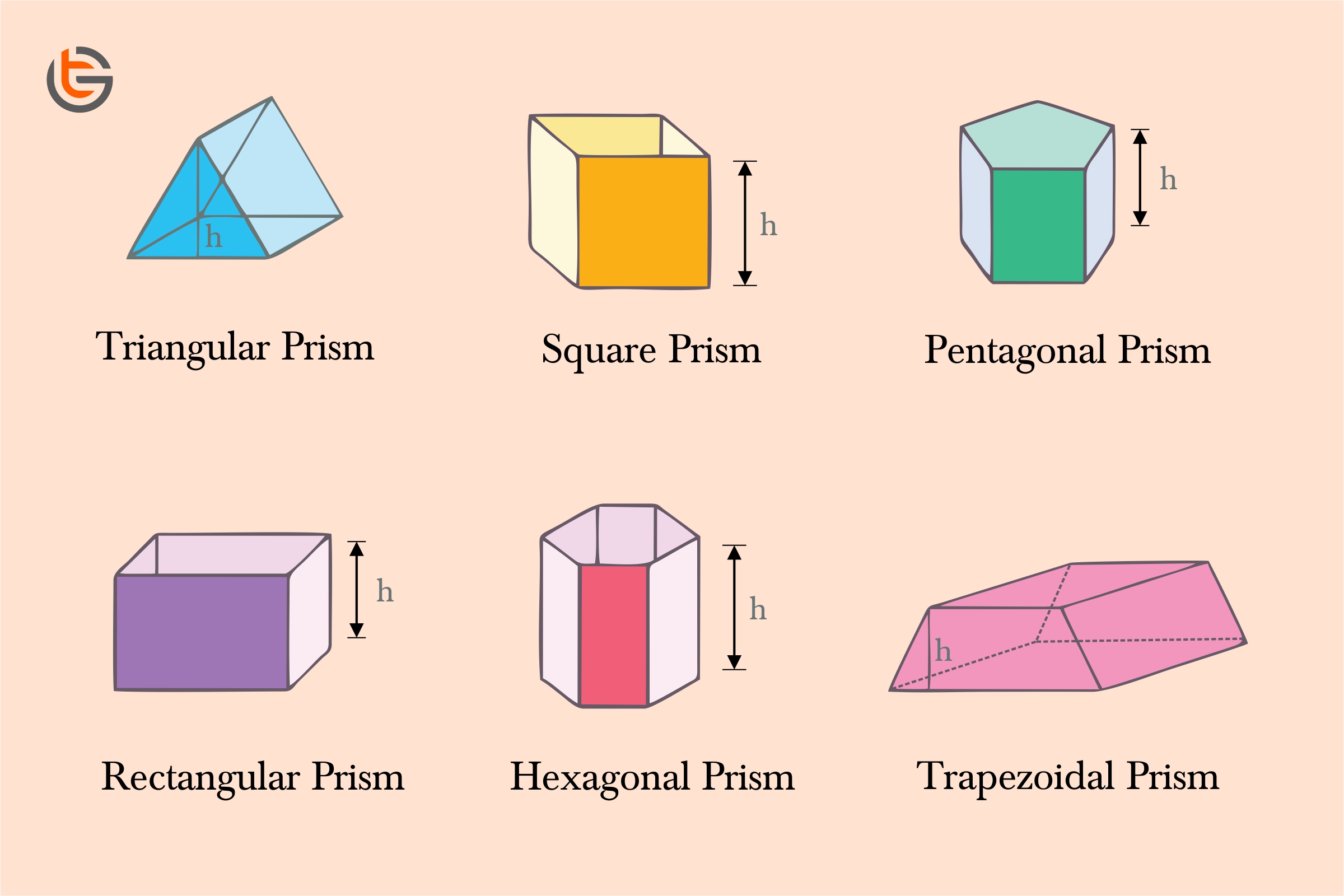

Prismatic powders are a unique class of materials characterized by their distinctly non-spherical morphology. Unlike spherical powders, which are commonly used in various applications, prismatic powders possess a multifaceted, elongated, or rod-like shape, influencing their properties and applications significantly. This characteristic shape impacts their flow behavior, packing density, and overall performance in diverse contexts.Prismatic powders exhibit a range of sizes and aspect ratios (the ratio of length to width).

The size distribution, often described by parameters such as average length, width, and aspect ratio distribution, is crucial in determining the final product’s properties and performance. A uniform size distribution is generally preferred for consistent results, although some applications may benefit from a broader distribution.

Manufacturing Methods for Prismatic Powders

Several methods are employed to produce prismatic powders, each offering unique advantages and limitations depending on the desired material and application. The choice of manufacturing method often depends on factors such as the desired particle size, shape, and material properties. These methods influence the final powder’s cost, quality, and scalability.

- Precipitation Methods: These methods involve the controlled precipitation of a solute from a solution, leading to the formation of crystals with a prismatic habit. Parameters such as temperature, pH, and concentration gradients are carefully controlled to influence the crystal growth and morphology. This approach is suitable for various materials, offering good control over particle size and morphology.

For instance, the precipitation of metal salts can produce prismatic metal oxide powders.

- Solid-State Reactions: These methods involve the reaction of solid precursors at elevated temperatures. The reaction conditions, including temperature, time, and atmosphere, dictate the resulting particle shape and size. This approach is commonly used for producing ceramic prismatic powders.

- Mechanical Attrition: This method involves the grinding or milling of larger particles to reduce their size and modify their shape. While not solely producing prismatic shapes, mechanical attrition can be used to refine the shape of pre-existing particles, making them more prismatic. This method is often employed to create prismatic powders from other shapes.

- Spray Drying: This technique involves atomizing a liquid suspension containing the desired material into a hot drying chamber. The rapid evaporation of the solvent leads to the formation of solid particles. Careful control of the spray parameters and drying conditions can result in prismatic powders. This is a widely used industrial method.

Materials Formed into Prismatic Powders

A wide variety of materials can be synthesized or processed into prismatic powders, each finding applications in specific fields. The selection of the material depends heavily on the desired properties and the intended application.

- Metal Oxides: Metal oxides such as zinc oxide (ZnO), titanium dioxide (TiO2), and tungsten trioxide (WO3) are commonly produced as prismatic powders due to their diverse applications in electronics, catalysis, and pigments.

- Ceramics: Various ceramic materials, including alumina (Al2O3), zirconia (ZrO2), and silicon carbide (SiC), can be produced in prismatic forms. Their high strength, hardness, and thermal stability make them suitable for applications in high-temperature environments.

- Metals: While less common, some metals can also be produced as prismatic powders. This is often achieved through specialized techniques like electrodeposition or chemical reduction.

- Polymers: Certain polymers can be processed into prismatic shapes through techniques such as melt extrusion and subsequent milling or fracturing. These polymeric powders find applications in additive manufacturing and composite materials.

Applications of Prismatic Powders

Prismatic powders, with their unique light-bending properties, find diverse applications across various industries. Their ability to create vibrant, iridescent effects makes them a valuable ingredient in cosmetics, paints, and artistic creations. This section will explore the specific uses and benefits of prismatic powders in these fields.

Prismatic Powders in Cosmetics

Prismatic powders are increasingly popular in cosmetic products due to their ability to enhance the appearance of skin and makeup. They are commonly incorporated into eyeshadows, highlighters, and lipsticks to create shimmering, multi-dimensional effects. The fine particles of prismatic powder subtly refract light, giving the skin a luminous glow and adding depth and dimension to makeup. This effect is particularly desirable for creating a highlight that catches the light, or for adding a touch of sparkle to eyeshadows without appearing overly glittery.

Furthermore, the use of prismatic powders can enhance the overall visual appeal and perceived quality of the cosmetic product.

Prismatic Powders in Paints and Coatings

In the paint and coatings industry, prismatic powders are used to create special effects and enhance the visual appeal of various surfaces. They are added to paints and coatings to achieve unique color shifts and shimmering effects, depending on the angle of observation. This can be particularly useful in automotive coatings, where the iridescent shimmer adds a premium look to the vehicle’s finish.

The impact on color is multifaceted, with prismatic powders not simply adding a single color, but rather a range of colors that shift and change depending on the light source and viewing angle. This creates a depth and complexity not achievable with traditional pigments. The texture can also be affected, creating a subtle sparkle or a more pronounced glitter effect, depending on the size and concentration of the prismatic powder.

Prismatic Powders in Art and Design

Artists and designers utilize prismatic powders to achieve unique visual effects in a variety of mediums. They can be incorporated into paints, resins, and other materials to create stunning, iridescent artworks. The ability of prismatic powders to shift color and reflect light allows artists to create dynamic and captivating pieces. Sculptors may incorporate prismatic powders into their work to add shimmering accents or to create the illusion of depth and movement.

In design, prismatic powders can be used to add a unique, luxurious feel to textiles, clothing, and accessories. The resulting effect is often described as having a “pearlescent” or “opalescent” quality. These special effects are often difficult to achieve using other techniques.

Comparison of Prismatic Powder Applications Across Industries, Prismatic powders

| Industry | Application | Advantages | Disadvantages |

|---|---|---|---|

| Cosmetics | Eyeshadows, highlighters, lipsticks | Creates luminous glow, adds depth and dimension, enhances visual appeal | Can be more expensive than traditional pigments, may require careful formulation to avoid clumping |

| Automotive | Paints and coatings | Creates unique color shifts and shimmering effects, enhances visual appeal, adds a premium look | Can be sensitive to UV degradation, may require specialized application techniques |

| Printing | Special effect inks, security printing | Creates iridescent designs, enhances security features, adds visual interest | Can be challenging to print consistently, may require specialized printing equipment |

Optical Properties of Prismatic Powders

Prismatic powders, characterized by their elongated, crystal-like structures, exhibit unique optical properties stemming directly from their shape and size. These properties are responsible for the often-observed iridescence and vibrant color shifts seen in many applications. Understanding these optical characteristics is crucial for effectively utilizing these materials in various industries.The shape of prismatic powders significantly influences their light scattering properties.

Unlike spherical particles that scatter light relatively isotropically (equally in all directions), prismatic particles exhibit anisotropic scattering. This means that the scattering intensity and direction depend on the orientation of the particle relative to the incident light. The facets of the prismatic crystals act as miniature mirrors and diffraction gratings, causing light to reflect and refract in specific directions, leading to the characteristic sparkle and iridescence.

This effect is amplified when the particle size is comparable to the wavelength of visible light.

Effect of Particle Size on Color and Iridescence

Particle size plays a critical role in determining the observed color and iridescence of prismatic powders. Smaller particles tend to scatter light more efficiently across a broader range of wavelengths, often resulting in a whiter or less intensely colored appearance. As particle size increases, the scattering becomes more selective, favoring specific wavelengths, and leading to more intense and saturated colors.

This is due to the interplay of diffraction and interference effects, where constructive interference of specific wavelengths results in enhanced color perception. For instance, larger particles might selectively scatter blue light more strongly, resulting in a blue hue, while smaller particles might produce a less saturated color or even appear white. This size-dependent color phenomenon is often exploited in the creation of pearlescent or iridescent effects in cosmetics and paints.

Comparison with Other Powder Pigments

Compared to other powder pigments, such as spherical pigments or amorphous powders, prismatic powders offer a unique combination of brightness, color saturation, and iridescence. Spherical pigments, for example, typically produce a more matte and less vibrant appearance, while amorphous powders may lack the directional scattering properties of prismatic particles. The highly ordered crystal structure of prismatic powders contributes to their superior optical performance, allowing for the creation of complex and visually striking color effects.

This difference in optical behavior is directly linked to the particle morphology and its impact on light-matter interactions.

Experimental Demonstration of Particle Size Effect

The following experiment aims to demonstrate the impact of particle size on the optical properties of a prismatic powder. A controlled experiment is crucial to isolate the effect of particle size and avoid confounding factors.

- Materials: A sample of prismatic powder (e.g., mica), sieves with different mesh sizes (to separate particles into various size ranges), a spectrophotometer or colorimeter, and a set of glass slides or Petri dishes.

- Procedure:

- Separate the prismatic powder into several size fractions using the sieves. Each fraction will represent a different particle size range.

- Prepare samples by spreading a thin, even layer of each size fraction onto the glass slides or Petri dishes.

- Measure the reflectance spectra of each sample using the spectrophotometer or colorimeter. This will provide quantitative data on the light scattering properties of each size fraction.

- Analyze the reflectance data to determine the dominant wavelengths and the overall color appearance for each size fraction. Compare the results across different size ranges.

This experiment will allow for a direct observation of the relationship between particle size and the resultant color and iridescence of the prismatic powder. The spectrophotometer data will provide objective evidence to support the visual observations.

Chemical Composition and Stability: Prismatic Powders

Prismatic powders, owing to their diverse applications, encompass a wide range of chemical compositions. Understanding these compositions and their inherent stability is crucial for effective utilization and long-term performance. This section will explore common chemical compositions, stability under various conditions, potential degradation pathways, and relevant safety considerations.The chemical composition of prismatic powders is highly dependent on their intended application.

For instance, pigments used in paints and coatings often consist of metal oxides like titanium dioxide (TiO2), iron oxides (Fe2O3, Fe3O4), or chromium oxides (Cr2O3), frequently in combination with other additives to enhance properties like dispersion and durability. In contrast, prismatic powders used in optical applications might comprise specialized materials like rare-earth doped phosphors or meticulously synthesized inorganic crystals with tailored refractive indices.

The specific composition dictates the powder’s optical, thermal, and chemical properties, directly influencing its stability and performance.

Common Chemical Compositions

Several common chemical compositions are found in prismatic powders. Metal oxides, as mentioned previously, are prevalent due to their stability, color, and availability. Examples include titanium dioxide (TiO2), known for its bright white color and high refractive index, and zinc oxide (ZnO), utilized for its UV-blocking properties. Other common compositions include various sulfides, such as zinc sulfide (ZnS), employed for its luminescent properties, and silicates, used for their thermal stability and inertness.

The choice of composition is driven by the desired properties for the final application.

Chemical Stability Under Various Environmental Conditions

The stability of prismatic powders is significantly influenced by environmental factors such as temperature, humidity, and UV exposure. High temperatures can lead to sintering or phase transitions, altering the particle size and morphology, and consequently affecting the optical and mechanical properties. High humidity can promote hydrolysis or oxidation reactions, particularly in metal oxides or sulfides, leading to degradation and performance loss.

UV exposure can cause photodegradation, especially in organic-based prismatic powders, resulting in color fading or loss of functionality. For example, titanium dioxide, while generally stable, can undergo photocatalytic reactions in the presence of UV light and moisture, potentially leading to surface modifications.

Potential Degradation Pathways and Methods to Improve Long-Term Stability

Several degradation pathways can affect the long-term stability of prismatic powders. These include oxidation, hydrolysis, photodegradation, and thermal decomposition. To enhance stability, various strategies can be employed. Surface coatings, such as silica or alumina layers, can act as protective barriers against moisture and oxygen. Doping with stabilizing agents can modify the crystal structure and enhance resistance to degradation.

Careful control of the synthesis process can result in powders with higher crystallinity and fewer defects, thereby improving their inherent stability. Proper storage conditions, such as maintaining low temperature and low humidity, can also significantly extend the lifespan of prismatic powders.

Safety Considerations Related to Handling and Use of Prismatic Powders

Handling and using prismatic powders requires appropriate safety precautions. Some powders may be toxic or irritating, necessitating the use of personal protective equipment (PPE) such as gloves, masks, and eye protection. Inhalation of fine powders can cause respiratory problems, and skin contact may lead to irritation or allergic reactions. Proper ventilation is crucial during handling to minimize inhalation risks.

Specific safety data sheets (SDS) should be consulted for each individual powder to determine appropriate handling procedures and emergency response measures. Disposal of prismatic powders should also follow established environmental regulations.

Notice lowes lawn mowers for recommendations and other broad suggestions.

Future Trends and Developments

The field of prismatic powder technology is poised for significant growth, driven by advancements in materials science, manufacturing techniques, and the expanding demands of various high-tech industries. Ongoing research and development efforts are focusing on enhancing the properties of existing prismatic powders and exploring novel applications that leverage their unique optical and chemical characteristics. This section will explore emerging trends, potential advancements, and the challenges and opportunities that lie ahead.Emerging applications for prismatic powders are continuously expanding beyond their traditional uses.

The development of more efficient and cost-effective manufacturing processes is also a key driver of innovation in this field. However, several challenges remain, requiring focused research efforts to fully unlock the potential of prismatic powders.

Emerging Applications in New Technologies

Prismatic powders are finding increasing use in advanced display technologies, including micro-LED displays and augmented reality (AR) devices. Their ability to precisely control light scattering and reflection makes them ideal for enhancing image quality and brightness. For example, the incorporation of specially designed prismatic powders into backlighting systems can improve the color gamut and contrast ratio of displays significantly, leading to more vibrant and realistic images.

In the field of biosensors, prismatic powders with tailored surface functionalities are being investigated for their potential in highly sensitive and selective detection of biological molecules. Their unique optical properties allow for the development of compact and portable diagnostic tools. Furthermore, research is underway to explore the use of prismatic powders in advanced photonic devices, such as integrated optical circuits and optical filters, leveraging their ability to manipulate light at the nanoscale.

Advancements in Manufacturing and Processing

Significant progress is being made in the development of more efficient and scalable manufacturing processes for prismatic powders. Techniques such as controlled precipitation, hydrothermal synthesis, and spray pyrolysis are being refined to produce powders with improved size uniformity, morphology control, and enhanced optical properties. For example, the use of advanced microfluidic devices allows for precise control over the crystallization process, leading to the production of highly monodisperse prismatic powders with superior optical performance.

Furthermore, the integration of artificial intelligence (AI) and machine learning (ML) algorithms into the manufacturing process is enabling real-time optimization and quality control, leading to higher yields and reduced production costs. This automation also allows for more precise control over particle size and shape, crucial factors in determining the final optical properties of the powder.

Challenges and Opportunities in Prismatic Powder Research and Development

Despite the significant progress, several challenges remain in the field of prismatic powder research and development. One major challenge is the precise control over particle size and shape distribution during synthesis. Inconsistencies in these parameters can significantly affect the final optical properties of the powder, leading to variations in performance. Another challenge lies in the development of cost-effective and environmentally friendly manufacturing processes.

Many current methods involve the use of hazardous chemicals and high energy consumption, making them unsustainable in the long term. However, these challenges also present significant opportunities. The development of novel synthesis methods and improved processing techniques could lead to the production of high-performance prismatic powders at lower costs and with reduced environmental impact. Furthermore, the exploration of new materials and compositions could lead to the discovery of prismatic powders with enhanced properties, opening up new applications and possibilities.

Potential Research Questions

The following research questions represent key areas requiring further investigation to advance the field of prismatic powder technology:

- What novel synthesis methods can be developed to produce prismatic powders with improved size uniformity and morphology control?

- How can AI and machine learning be effectively integrated into the manufacturing process to optimize production efficiency and reduce costs?

- What new materials and compositions can be explored to enhance the optical and chemical properties of prismatic powders?

- How can the environmental impact of prismatic powder manufacturing be minimized through the development of more sustainable processes?

- What are the long-term stability and durability of prismatic powders under various environmental conditions?

Illustrative Examples

Prismatic powders, due to their unique microstructures and optical properties, exhibit fascinating visual characteristics under varying lighting conditions. Their appearance is highly dependent on the interplay of light scattering, diffraction, and interference within the individual particles and their collective arrangement. This section will explore these visual aspects and provide a microscopic view of a typical prismatic powder sample.The color and iridescence displayed by prismatic powders are not inherent properties of the material’s chemical composition alone, but rather a consequence of their physical structure and how light interacts with it.

This interaction produces a vibrant display of color that shifts depending on the angle of observation and the nature of the light source.

Appearance Under Different Lighting Conditions

The appearance of prismatic powders varies dramatically depending on the type of illumination. Under direct sunlight, the intense, broad spectrum of light causes the powders to exhibit a vibrant and intense iridescence. Multiple colors might be observed simultaneously, shifting as the angle of observation changes. This effect is due to the diffraction of sunlight by the multifaceted prismatic particles, causing different wavelengths of light to be reflected at different angles.

For example, a sample of mica powder might show a strong shift from gold to green depending on the viewing angle under direct sunlight. In contrast, under incandescent light, the warmer, yellowish-orange tones of the light source tend to dominate the reflected light. The iridescence might be less pronounced, and the overall appearance might appear more muted or less saturated.

The color shift is less dramatic than under sunlight because the limited spectrum of incandescent light provides fewer wavelengths for diffraction. Fluorescent light, with its cooler, whiter light, produces a different effect again. The colors might appear slightly more pastel or washed out compared to sunlight, and the iridescence could be somewhat subdued, though still visible. The specific color shifts and the intensity of iridescence depend on the size, shape, and refractive index of the prismatic particles, as well as their orientation within the sample.

Microscopic Structure of a Prismatic Powder Sample

Microscopic examination reveals that a typical prismatic powder sample is composed of an aggregate of individual particles exhibiting a characteristic prismatic or plate-like morphology. These particles are typically elongated or flattened, with multiple flat faces or facets. The size of the particles varies depending on the specific material and processing methods; sizes range from several micrometers to hundreds of micrometers.

The arrangement of the particles within the powder sample is often irregular and non-uniform, with particles randomly oriented in various directions. This random orientation contributes to the overall iridescence effect, as light interacts with the particles at diverse angles. Consider, for instance, a sample of synthetically produced rutile TiO2. Microscopic imaging would show elongated, prismatic crystals, often exhibiting a slightly translucent appearance with sharp edges and facets.

The size distribution would likely be relatively uniform, given controlled synthetic conditions. The individual crystals would be densely packed but not necessarily perfectly aligned, leading to the characteristic iridescence. A detailed analysis might also reveal surface imperfections or minor variations in crystal structure, contributing further to the complexity of light interaction.

In conclusion, prismatic powders represent a fascinating intersection of material science, optics, and industrial applications. Their unique light-scattering properties, stemming from their precise shapes and sizes, unlock a spectrum of possibilities across diverse sectors. From the subtle shimmer in cosmetics to the bold brilliance in high-tech applications, these materials continue to evolve, promising exciting advancements in both their manufacturing and utilization.

Further research into their stability, novel applications, and sustainable production methods will undoubtedly shape the future of this dynamic field.